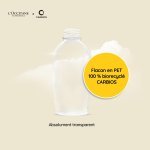

A few weeks after the launch of the construction of its first factory, which is scheduled to be fully operational in 2026, Carbios unveils a bottle in transparent PET made entirely from enzymatic recycling for a shower oil from the Amande range by L’Occitane en Provence. The innovation will be showcased at the Édition Spéciale by Luxe Pack show on 4-5 June 2024 in Paris.

Enzymatic depolymerization

The bottle’s production began with the supply of PET waste (already collected, sorted and prepared) to the Carbios industrial demonstrator in Clermont-Ferrand, France. The waste used consisted of colored bottles, multilayer trays and mechanical recycling residues, none of which are currently recycled using conventional technologies.

Using its biorecycling technology, Carbios deconstructed the PET waste into its original monomers, PTA [1] and MEG [2]. The resulting monomers were then repolymerized into new, fully recycled PET.

Similar to virgin PET

In Oyonnax, France, these resins were blow-moulded by Pinard Beauty Pack to create bottles according to L’Occitane’s specifications, and then filled with its shower oil at its Manosque plant, in the south of France.

“This bottle was blow-moulded under the same conditions and with the same parameters as virgin or mechanically recycled PET, a considerable advantage for the deployment of Carbios’ technology. We’re seeing strong demand for high-quality recycled PET which can be used to produce the same applications as with virgin PET,” said Paolo Coelho, Plant Director, Pinard Beauty Pack.

100% circular PET

Carbios’ technology accelerates the transition to a circular economy by offering an alternative to oil-sourced PET and a circular PET recycling solution that reduces CO2 emissions by 57% compared to virgin plastic production [3] and for every tonne of recycled PET produced, 1.3 tonnes of oil are avoided.

Thanks to its enzyme optimized for efficient PET degradation, Carbios’ depolymerization technology can handle all types of PET waste, including coloured, multilayer or textile waste that cannot be recycled with current technologies. It therefore complements mechanical recycling technologies. Furthermore, the two monomers produced (PTA and MEG) make it possible to recreate recycled PET products suitable for food contact and of identical quality to those of petroleum origin.

For L’Occitane en Provence, the creation of this bottle marks a key step in achieving its commitment of 100% retail bottles made from 100% post-consumer recycled PET by 2027.